A collaborative approach to achieve your objectives

Offering a comprehensive range of services, you can trust your project is in safe hands with Barnett Engineering.

Meeting your specific requirements

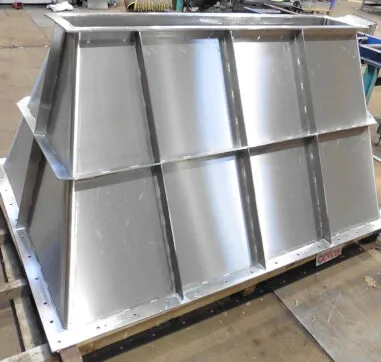

When choosing a partner for your steel fabrication works, it’s essential to know that they have the capabilities to match your specific requirements and ensure the highest quality build.

- Welding – MIG, TIG, and MMA

- Sheet Metal and Steelwork – cutting, bending, rolling, folding, drilling

- Mild Steel, Stainless – fabrications and repairs

- CNC Profiling – plasma and laser, as quick as we can draw it

- AutoCAD – taking your designs to production

- Surface Finishing – shotblast, beadblast, spray painting, powder coatings

- Belzona Coatings

– a wide range of high-tech protective solutions for industry

Your individual needs and requirements are always a priority, and our AutoCAD design and review process allows us to ensure you are 100% happy with the design before any fabrication commences.

Cost effective, reliable solutions

By choosing Barnett Engineering for your steel fabrication works, you will experience a wealth of benefits including:

- Good communication and a fast response – ensures an reliable and rapid turnaround.

- On-site – for minimum disruption

- Large projects – skills, capabilities, space, and transport

- Small jobs – one-offs or batch production

- Flexible approach – to minimise any disruption

- Skilled tradesmen – so your project is right first time

- Site labour – for fabrication and installation

Whether it’s a small job or you need us to urgently commence work on site, we approach every project with the same level of passion and attention to detail, ensuring projects are delivered on time.

"We have had a very close working relationship with Barnett Engineering going back over more than 40 years. This involves early design work on projects, budgeting costs, fabrications both large and small, trial assembly of installations prior to shipping to site and liaising on quality of workmanship as project proceed. Long standing personal relationships and co-operation have been an important factor over many years."

Process Engineering Specialists